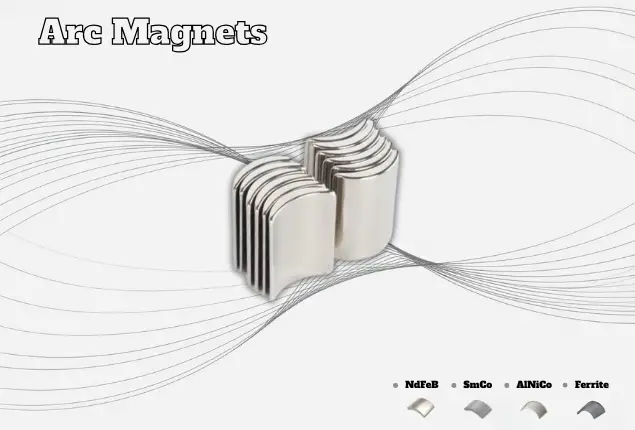

Arc magnets are a special shape of magnets with a curved structure. This unique design makes the magnetic field strength highest at the central axis and gradually weakens at the edges.

Magnetic Field Characteristics

Shape: The magnetic field of an arc magnet is projected in a semicircular shape, suitable for annular or cylindrical equipment, providing uniform and concentrated magnetic force.

Strength: The magnetic field strength is measured by the Gauss value. The higher the Gauss value, the stronger the magnetic force. High-end arc magnets can reach a magnetic field strength of thousands of Gauss to meet the needs of high-performance applications.

Distribution: The magnetic field gradually decays from the center axis to the edge. The magnetic field distribution needs to be considered during design to optimize equipment performance.

Material Type

The performance of arc magnets depends largely on the material selection. There is a trade-off between magnetic force, temperature resistance and cost for different materials:

NdFeB: Known for its extremely high magnetic force, it is the strongest permanent magnet material and is suitable for applications that require maximum magnetic field strength. However, it has weak high-temperature resistance (usually ≤175°C) and is susceptible to corrosion, requiring surface coating protection.

Samarium Cobalt (SmCo): It has excellent high temperature resistance (up to 350°C) and corrosion resistance, suitable for extreme environments, but it is more expensive and has slightly lower magnetic force than NdFeB.

Aluminum Nickel Cobalt (AlNiCo): It has good durability and medium magnetic force, suitable for traditional industrial applications, and has moderate temperature resistance (up to about 500°C).

Ferrite: Made of a mixture of iron and ceramic materials, it is inexpensive, easy to obtain, has a temperature resistance of about 80°C, but has a weak magnetic force, making it suitable for cost-sensitive applications.

Read Also: Slot’s Playing Philosophy Convinced My Son To Choose Liverpool –Wirtz’s Father

Main Applications

- Automotive

- Generators

- Magnetic Separators

- Medical Devices

- Sound Systems

- Household Appliances

Key Factors in Selecting Arc Magnets

When choosing arc magnets, there are several factors that need to be taken into account to maximize the performance of the device in which they are going to be used.

The selection of the right material is very important because a particular type of magnet (made of neodymium, samarium cobalt, alnico, or ferrite) will have certain magnetic strength, temperature resistance, and price. Therefore, the selection of the appropriate material should be based on the assumed use of the magnet.

Environmental adaptability is of equal significance

Humidity, temperature, and exposure to corrosive chemicals imply that the right material should be chosen, and various protective surface treatments. The performance of a magnet is primarily determined by its magnetic strength, and the decision of the right gauss level is guided by the necessity of the device in order to attain the desired magnet field strength.

Temperature during operation

In addition to that, the magnet has to be able to work in conditions that are changing without losing its magnetic properties, neodymium magnets generally work well at temperatures that are up to 175°C, while samarium cobalt magnets can operate at higher temperatures.

Geometric compatibility

The arc length, radius, and thickness of the magnet have to be exactly those of the device to be able to fit perfectly and get maximum efficiency. If the users go through the list of factors such as material selection, environmental adaptability, Gauss value, operating temperature, and geometric fit, they will have no problem in choosing reliable and high-performance arc magnets for their specific needs.

Summary

Arc magnets have been globally accepted as having a wide potential application in various fields such as industry, medicine, consumer products, and scientific research due to their novel design, strong magnetic field and variety of materials. While picking up arc magnets, one has to consider various factors like the nature of the material, the strength of the magnetic field, the highest temperature of operation, size compatibility, and the cost, which all influence the final decision. It is highly advisable to utilize reliable magnet suppliers to guarantee the performance of the magnet and its reliability during the entire time of use.